Bamboo Flooring

By Stan Hulin

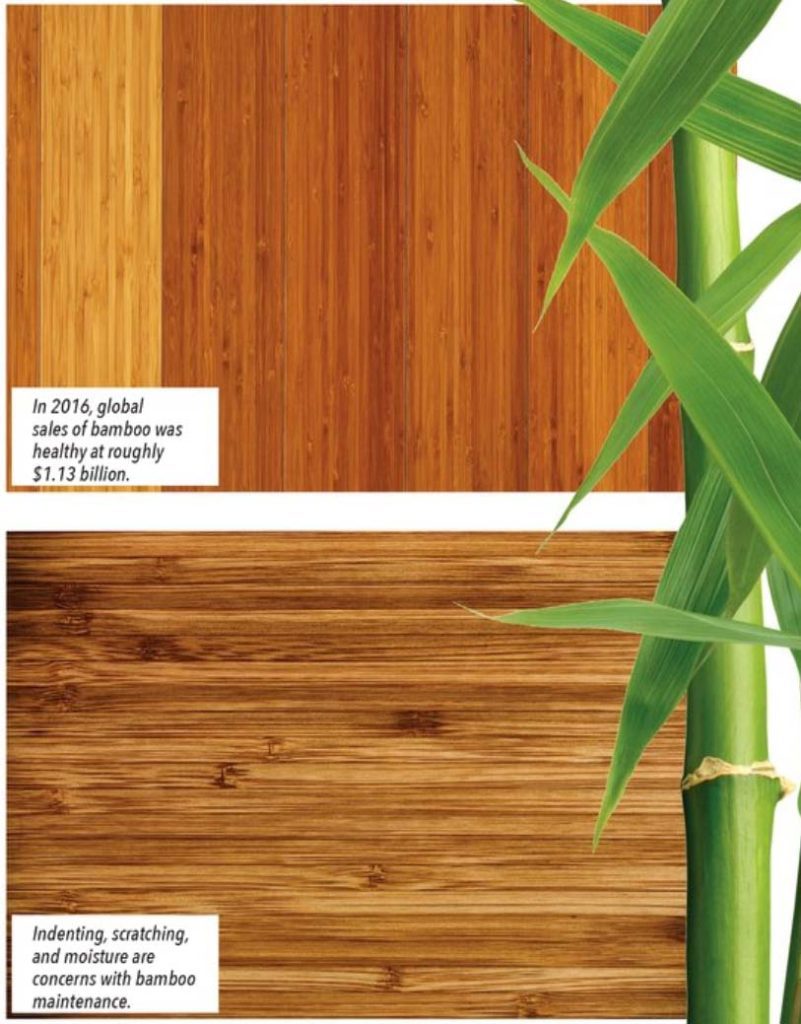

Bamboo flooring arrived in the United States during the 1990s and has made a considerable impact on the flooring market. In 2016, the global sales of bamboo flooring were roughly $1.13 billion.

Although bamboo flooring was initially met with a certain amount of skepticism, it is now a force to consider. The advancements in manufacturing processes have increased its durability, which make it a popular choice in both residential and commercial environments. Because of its rapid growth, it is considered an “environmentally friendly” flooring material.

Most people assume that bamboo is a tree, but it is really a grass. The stem or trunk of the bamboo plant is called the culm. It has a series of hollow cylindrical chambers that are jointed (called nodes) and tapered to the top. The most common species used for flooring material is Moso (phyllostachys edulis) bamboo, a species capable of growing to 60 feet with a diameter of five to seven inches that can be harvested every three to eight years.

For bamboo to be used as a flooring material, it must possess the properties of durability, which equate into hardness. Natural bamboo ranges from 1,380 to 1,410 on the Janka Hardness Scale, which is somewhere between the hardness of white oak and hard (sugar) maple. Carbonized bamboo is somewhat softer, with a rating range between 1,010 and 1,120, which is harder than heart pine but softer than black walnut.

Facts: The Janka Hardness Scale produces a rating value by measuring the pounds of force required to embed half the diameter of a 11.28 mm steel ball into wood. The ratings range from as low as 100 (balsa) to 4,500 (guaiacum).

Many factors play into the hardness of bamboo, which is why it has such a wide range of hardness. When it is harvested in its growth cycle and how it is manufactured are key components to the hardness factor. Additionally, there are very few laws that govern the quality control of products coming from foreign nations, making it difficult to have the consistency in hardness.

Bamboo flooring construction

The manufacturing process begins with the culm or stalk of the bamboo being sliced, then cut into strips and steamed under pressure to sanitize the product. Carbonized bamboo undergoes the process for a longer period, which produces the darker colors associated with carbonization; however, the additional steaming also reduces the hardness rating.

These strips are then kiln-dried and glued together into boards using a combination of heat and pressure. Horizontal bamboo flooring is achieved by gluing the strips face up, which allows the nodes to be visible. Vertical bamboo flooring is achieved by gluing the strips side by side, which gives the floor more of a striped appearance.

Other types of bamboo include engineered bamboo and strand- woven bamboo.

Engineered bamboo is common in horizontal bamboo in which the cross-layered under layers can be made of less expensive softwoods or lower-grade bamboo and may contain three to seven layers. Strand woven bamboo is made by gluing shredded fibers from the culm together under extreme heat and pressed into boards. The result is a very dense and durable product that can be either made from natural or carbonized bamboo.

The boards of glued strips are then milled to make the tongue-and-groove slats used for installing the flooring material. The final processes are to stain and finish the flooring. The finishes used for bamboo flooring are generally urethane or polyurethane coatings that, in some cases, contain aluminum oxide that gives the flooring a very durable finish. Due to the inconsistencies in manufacturing processes, you will find some bamboo flooring materials are less durable than others.

Bamboo flooring maintenance

The primary concerns when maintaining bamboo flooring are indenting, scratching, and moisture. Some bamboo can be scratched easily with a coin or indented with your thumbnail. Most wood floors have the same issues. There is very little a floor maintenance technician can do about indenting, scratching, and damage in general. High heel strikes and objects being slid across the floor will cause these conditions and once they have occurred, they are there. Owners of bamboo flooring may wish to consider using area rugs or walk-off mats to help combat abrasion of the surface. This is especially true of walk-off mats in entrance areas that are exposed to the outside elements.

Moisture is another issue that impacts maintenance of bamboo. When wet service procedures are performed, it is important to remove as much solution from the floor as possible.

Much of the problems with bamboo flooring has to do with the tongue-and-groove construction. Although the top of the bamboo flooring is sealed with durable urethane or polyurethane coating, what’s underneath is not. Cleaning solution will seek the path of least resistance and migrate to the lowest point. This means moisture will seep between the joints where the slats are joined and continue downward to the subfloor. Excessive moisture may cause discoloring, warping, or cupping.

Maintenance for bamboo, like most wood floors, is relatively easy: Dust mop, sweep, or vacuum regularly, and damp mop with neutral cleaner solution when needed. For heavy soil, wet mop and rinse. When this service procedure is performed, remove as much solution from the floor as possible, and always finish with a damp mop to remove any excess moisture.

Periodic maintenance may incorporate a light or medium scrub using neutral cleaning solution and a white or red pad. When performing this service procedure, remove excess solution with wet vacuum, and finish solution removal with a damp mop.

The construction of bamboo limits the restorative processes. The polyurethane coatings are extremely hard and durable but not indestructible. Over time, the appearance of the bamboo will decline, and additional maintenance may be required. Engineered bamboo has a thin veneer of bamboo on the surface; therefore, aggressive sanding cannot be done.

Although restorative maintenance in the form of sanding and refinishing is not recommended, a superficial abrasion with a surface-preparation pad or fine-sanding screen followed by a coat of polyurethane may enhance the product. However, these service procedures should be performed by trained, professional technicians.

Bamboo flooring as we know it today may be relatively new to the industry, but it sure looks like it is going to be here for a while. Understanding what it is, how it is manufactured, and its properties and characteristics may help floor maintenance technicians provide better services for their customers who have purchased bamboo.

Stan Hulin has over four decades of hard floor maintenance, services, training, education, sales and marketing, and management experience with companies such as ABM, DuPont, and milliCare. He is president and CEO of Future Floor Technology Inc. and the League of Hard Flooring Professionals. He can be reached at [email protected].