What to Know About Asbestos

By Mark Drozdov with Amanda Hosey

Some people know what they know; some know what they don’t know; and some don’t know what they don’t know. If you work in the restoration industry, here is something important to know: Because of the interaction with building materials, restoration is one of the occupations most at risk of exposure to asbestos, a known carcinogen.

Many are surprised to learn that asbestos is not illegal in the U.S. In fact, it is still used in small amounts and often is found in building materials shipped from other countries with higher allowable limits.

Despite this, there are some in the industry who either know they are not knowledgeable enough about asbestos (and choose to stay that way) or do not know they should be better educated on the issue. This article aims to fill in some gaps in general asbestos education and to encourage those reading it to seek out further education and training if needed.

[two_third]

This is part of a larger series on PALMS (Look for more articles in this series in upcoming issues.), which is an acronym used to discuss these contaminants of concern:

- PCBs/Pandemic

- Asbestos

- Lead/Legionella

- Mold/Metals

- Silica

I first developed the PALMS acronym during my work testing and supporting restoration and remediation efforts following the 9/11 attacks. At Ground Zero, it was mindboggling trying to test for everything. Eventually, the list of 300 elements shrunk to what was referred to as contaminants of concern. The PALMS acronym arose from those contaminants of concern because, with all the regulatory oversight at Ground Zero, it was clear this list was the list for use on any project. The list has evolved in the time since to keep up with changing concerns. By recognizing and eliminating each of the contaminants from the list prior to beginning a restoration project, we can ensure the safest site possible.

Asbestos testing should always be performed before a restoration project begins. One does not want to be unpleasantly surprised by the presence of asbestos and have your work or well-being permanently damaged. Unknowingly disturbing asbestos-containing material* (ACM) is hazardous to health of all who breathe it. The EPA says there are more than 3,000 construction materials that could contain asbestos, but the Restoration Industry Association (RIA) narrowed this to a list of the 30 most relevant to the industry, often referred to in the field as “The Dirty 30.” (See sidebar.)

Knowledge of asbestos serves only to benefit a restoration company.

Download the RIA’s Asbestos Fact Sheet.

Awareness and testing

Testing for asbestos is not where preparedness begins. Recognition of potentially hazardous materials is where a project must start. To this end, all restoration professionals should have, at minimum, asbestos awareness training (more on this later) to instill in them the knowledge necessary to recognize presumed asbestos-containing materials (PACM), which must then be tested by a qualified professional.

Those qualified to test for asbestos vary in name by location and certifying body. For example, I am an accredited inspector for asbestos according to the EPA; in New York state, I am a certified asbestos inspector; and in New York City, I am a certified asbestos investigator. Regardless of the name given to them, a qualified professional is necessary to test for asbestos when PACM are present on a jobsite. If an individual is not available to test—or a company chooses not to or forgets to test—then all material must be treated as if it contains asbestos. When material contains or is presumed to contain asbestos, only asbestos abatement-trained, certified professionals may interact with it.

[/two_third]

[one_third_last]

The ‘Dirty 30’

– Pipe/Duct insulation

– Boiler insulation

– Gaskets on boiler systems

– Ventilation systems

– Floor tiles

– Linoleum flooring

– Mastics and glues

– Asbestos roofing material

– Roofing tar/Asphalt

roofing materials

– Cement roofing

– Cement siding

– Caulking and sealants

– Wall or ceiling plaster

– Gypsum board

– Spackle

– Textured ceilings

(popcorn)

– Fire doors

– Blown-in/Vermiculite

insulation

– Sprayed-on fireproofing

coatings

– Fire blankets and clothes

– Cement pipes or boards

(transite)

– Woven cloth-wire

insulation

– Ceiling tiles

– Laboratory countertops/

sinks

[/one_third_last]

Responsibility and consequences

In a way, there are many parties responsible for ensuring suspect materials are tested for asbestos. The facility owner is ultimately responsible for all that happens in their facility, but they will often claim ignorance—that they did not know to do it or that they thought the contractor was handling it. Likewise, a contractor might claim they believed the materials had already been tested.

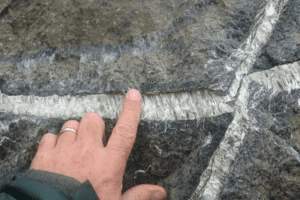

Image courtesy of Mark Drozdov.

However, if a restoration company begins a project without testing and does not treat suspect material as PACM, that company is then responsible and subject to the consequences, both legal and moral, that arise. Sometimes people make honest mistakes where asbestos is involved, but not knowing the law does not alleviate them from taking legal, proper steps.

At the end of the day, these mistakes could be considered criminal because we are dealing with health and safety. People have been imprisoned, faced large regulatory fines, and been found legally responsible financially for various missteps involving asbestos.

Often, when people make these mistakes, they try to make things better or hide or change the narrative of what happened in an effort to protect themselves, but this only makes matters worse, as they are then venturing into fraud.

Training and working

All restorers should understand asbestos basics, which include what are considered hazardous materials, the restrictions associated with dealing with those hazardous materials, and the implications of not handling the situation properly.

Asbestos awareness training is not only important for restoration professionals to have, but also is required by law. It is the minimal requirement of training and understanding necessary to perform the work, and every restoration technician and supervisor should have it. Awareness training teaches how to spot hazardous materials, allowing a technician to know when testing must be performed before work can begin—in order to protect themselves, building occupants, and the company.

Image courtesy of Mark Drozdov.

Anyone can get trained in asbestos abatement. There are no prerequisites, and training generally takes only four days for technicians and five days for supervisors. Training consists of learning federal, state, and local regulations; proper abatement techniques; PPE best practices; disposal requirements; and more, as well as participation in hands-on exercises for varied aspects of the work.

However, restoration companies looking to add asbestos abatement to their service offerings should first and foremost realize that asbestos work is a completely different business, and no one should take it lightly. While asbestos abatement training is fairly straightforward, the work itself is not so easily added. One cannot simply go through a training program and begin providing the service the next day.

All personnel involved in the abatement process must be trained and certified. Supervisors must be designated and receive advanced training and certification. Specialized equipment is required. The company must put in place protocols, receive licensing, and acquire needed insurance. Again, asbestos abatement is a different business from standard restoration work.

Asbestos abatement work requires organization and planning. Companies must always have a plan of attack to prevent any inadvertent spread of asbestos-containing material dust. The work also requires permits for each individual project. Companies must file plans for the work with the authority having jurisdiction (AHJ). The AHJ on a given job could be the municipality, the state, and, depending on the quantity, the EPA.

When PACM is recognized by a restoration company, and qualified testing confirms the presence of asbestos (or testing was not performed, leaving suspect materials to be treated as asbestos-containing by a certified firm), the restoration company cannot legally disturb those materials. ACM is often not throughout an entire building (i.e., it could be the floor tiles; pipe, boiler, or duct insulation; a wall in a boiler room; etc.), so the traditional restoration company can generally continue with caution performing most of their work as long as the asbestos-affected areas are properly isolated and there is no crossover. Again, only asbestos-certified firms are permited to handle ACM.

Restorers and their obligation

According to the Mesothelioma Center, there are more than 39,000 asbestos-related deaths in the United States alone each year. Nowadays, it is simply unacceptable and illegal for a restoration professional not to have awareness-level training regarding asbestos hazards. This basic training can save countless lives—those of staff, their families (due to secondary exposure), and building occupants.

When I present my yearly PALMS update, there is always a large crowd in attendance. Some might wonder what there is to discuss yearly about well-established hazards. At the 2021 update in February, there were more than 100 high-level professionals in the field, people who do this work every day, still learning new things.

Asbestos work is a highly regulated area, and restorers should feel neither intimidated by it, nor overly confident that they know everything. There is not a single person who can claim to know everything about the subject. Proceed with caution and consult with experienced, licensed professionals to ensure there are no mistakes.

* According to OSHA/EPA, material containing more than 1% asbestos is asbestos-containing material (ACM).

Look for more articles in this series on PALMS in future issues of Cleanfax.

Mark Drozdov is known for his diverse work in environmental, health, and safety projects worldwide including HazMat remediation; industrial hygiene; hazard/risk assessment; and compliance training, certification, and audits. He actively contributes to the AIHA/RIA/IICRC Crisis-Response Joint Task Force, IICRC Board of Directors, ISO infection control and EHS standards, and AIHA government relations. Drozdov’s PALMS program is the go-to method for dealing with contaminants of concern. He has received multiple awards and commendations, including for his work at Ground Zero. Connect with him on LinkedIn or email him at [email protected].

Amanda Hosey is the managing editor of Cleanfax. She has worked as an editor and writer for more than a decade, including six years with Cleanfax. Reach her at [email protected].