The Technician Personal Tool Inventory List

By Steve Toburen

Like most cleaning or restoration contractors, you probably want to get off the truck. (Who can blame you?) After all, personally doing the daily work in your company is very likely not your highest and best use.

Once you are off the truck, your new focus on sales and management will mean more business. So, you’ll likely buy more vans and equipment. Great! Building a business that could run without me was one of the huge joys of my life. Now your growing business will hum along nicely while cranking out happy, delighted cheerleader customers along with hardworking, loyal employees and tons of net profits for you.

Unfortunately, it isn’t (and won’t be) that easy.

Your challenges

Once you’re no longer on the truck, you inevitably lose some control of what’s happening on your truck(s). Your most urgent focus? Controlling the essential relationship between your techs and your customers when you’re not there. (Check out my Residential Moment of Truth Checklist in the July 2018 issue of Cleanfax.)

However, production logistics matter, too, and in a rapidly expanding company that’s painfully growing into a critical mass business, it is easy for the little things to fall apart. For example, stuff breaks out there in the field. True, many of your surprise repairs can be avoided with a routine Daily Maintenance Checklist (in the October 2018 Cleanfax) performed back at the shop, but stuff still happens. To finish the job and stay on schedule, your tech must make an emergency repair.

The tech heads to the truck’s toolbox, and disaster strikes! Too often, I received panicked calls like these from my techs, “Steve, the wrench to clean out my wand’s spray tip is missing!” or “I can’t cut the carpet’s seams to pull the soaked pad since the carpet knife isn’t in the van toolbox!”

My missing tool problem was seriously impacting production, angering customers, and damaging employee morale. Even worse, the lost tools created incessant bickering, as in, “Two days ago, I was on this van, and it had a carpet knife then. Charlie must have lost it yesterday!” Plus, constantly replacing lost tools was costing me a fortune.

Steve’s solution

Like many cleaning and restoration contractors, my techs often changed trucks depending on workloads and emergency call outs, so each truck would possibly have a different crew every day.

My first impulse? Have each truck’s crew go through the tools (and everything else on the truck), checking each item off on a detailed list… every single morning. You know how many individual tools/ chemicals and pieces of equipment there are on a typical cleaning or restoration van. It quickly became obvious that my detailed daily checklist procedure was impractical at best.

Then inspiration struck — I realized the root cause of my missing tool challenge was no one was being held accountable. The problem was each truck had its own toolbox, and the tools belonged to the truck, not an individual employee.

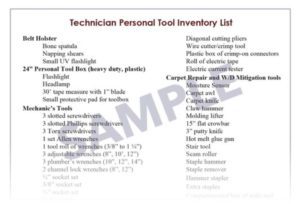

I bit the bullet and bought each individual tech his or her own set of tools. I gave all field employees their own mechanics tools (screwdrivers, pliers, wrenches, socket sets, etc.) as well as carpet repair tools (carpet awl and knife, hammer, molding lifter, staple hammer, etc.). The tools were in a heavy plastic, rustproof, 24-inch toolbox that stayed with the assigned tech during a work day.

Some heavier/more expensive tools were still assigned to each truck, such as a carpet knee kicker and seaming iron. Power stretchers stayed in our warehouse unless specified on the tech’s Production Day Sheet (January-February 2018 Cleanfax).

My secret sauce after giving each tech their very own toolbox? They also signed a Technician Personal Tool Inventory List. This contract listed out each personal tool assigned to the tech along with two essential phrases:

- “I, [name here], acknowledge receipt of the tools and equipment listed above.”

- “I recognize that any loss or damage will be deducted from my employee efficiency bonus.”

- Note that it is illegal virtually everywhere to deduct any loss or damage caused by an employee from his or her base paycheck — no matter how stupid or careless your worker’s actions may have been. However, most states allow money to be deducted from a bonus.

By assigning each tech their own personal tools and getting a signed Technician Personal Tool Inventory List — along with doing a formal inventory of each tech’s tools once a month — I finally was holding my employees personally accountable.

After all, as the business owner, I was accountable 24/7. All I wanted to do was have some shared accountability in my company. Remember, my goal was a business that would run smoothly without me.

The result

The personal accountability that the Technician Personal Tool Inventory List introduced literally transformed my company:

- My techs started taking care of (and not losing) their own tools.

- Our efficiency went up due to having the right tool with the right person at the right time.

- Our net profits dramatically increased so we could pay our workers more with a much higher employee efficiency bonus, and morale soared.

Adding this list cut my high blood pressure by 40 points because I wasn’t screaming at my employees and/or fuming about their careless attitude and general stupidity. My business was enjoyable again.

Implement this Technician Personal Tool Inventory List into your business infrastructure, and you’ll have happier, more motivated employees; your customers will be impressed; and your daily life will be fun again as you grow your company into a highly profitable business.

Steve Toburen started and ran a world-class cleaning and restoration firm for over 20 years. He is now the director of training for Jon-Don’s Strategies for Success program, which includes a complete, turnkey business infrastructure for cleaning and restoration companies. Toburen also founded HomeFrontSuccess.com, a resource portal with training programs for contractors working in customer’s homes. Reach him at [email protected].