The Equipment Repair Sheet

By Steve Toburen

Click to email [email protected]

Running my cleaning and restoration business always reminded me of a rowdy, out-of-control carnival. I’d first play the whack-a-mole game — smack one mole (problem for me) down, and immediately another mole would pop up in another spot. And then I would morph into a performer with a dozen spinning plates on top of slender poles, desperately trying to keep everything going!

Keeping your small service business running smoothly is a huge task, and equipment repair is just one of many challenges to master. The answer is a written business infrastructure comprised of systems and procedures to organize your employees’ daily work. This routine will make their lives easier. (And it will cut 40 points off your high blood pressure, too!) You’ll also be well on your way to an extremely profitable critical mass business (a company that will run without the owner being there 24/7) that can run smoothly without you.

Your challenges

Your phone is ringing off the hook. Jobs are coming in. Congratulations! Many cleaning and restoration contractors struggle with keeping a steady flow of jobs coming in, but you’ve done it. Great work.

But wait… now your techs need to reliably produce this work while (hopefully) consistently delighting customers. All this means your company needs working vehicles, equipment, and tools. Cue the threatening music because trouble waits around every corner.

Your techs are under pressure. For example, a sprayer, cleaning wand, or dehumidifier isn’t working, which means it gets brought back to the shop, and your usually running-behind employee grabs a different unit and zooms back out to the client.

But wait… the non-working item doesn’t get fixed, so it sits in the shop gathering dust with no ROI on your investment. Or even worse, another unsuspecting tech takes broken equipment back out on the job, so the vicious cycle repeats itself again and again, much to your frustration.

Do any of the above points sound familiar? Non-working equipment going back out into the field is inefficient, demoralizing for staff, and creates a negative moment of truth. (See my July 2018 Cleanfax article.) Plus, it destroys profits!

Steve’s solution: The Equipment Repair Sheet

I realized I needed to nail down where problems started. With sending non-working equipment back out into the field, the problem started when a tech first realized, “Dang. This air mover won’t turn on!”

So I developed simple troubleshooting procedures that even an under-pressure, non-mechanically inclined employee could follow:

Does the customer’s outlet have power? Is it a “switched outlet”?

Is power getting to the airmover’s motor? Can you hear a hum when turned on?

Unplug the cord. Can you move the fan by hand?

But honestly, I didn’t want techs rebuilding broken stuff in their customer’s living rooms. They had work to finish and a schedule to keep, so it needed to be swapped out or have another working item brought to the tech.

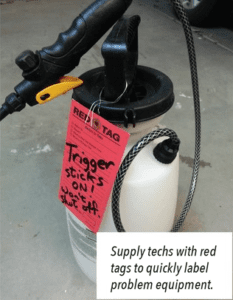

But before the technician puts the broken tool or equipment back into the truck, make sure it gets “red-tagged.” Red tags are simple, 3-inch by 6-inch cardboard tags with a wire attached. (Get them at office supply stores, or order them online.) On the tag, the tech should write the date, description of the problem (i.e., “leaks,” “doesn’t hold pressure,” “won’t run,” etc.), and the tech’s name.

Our field technician should next fill out an Equipment Repair Sheet (ERS) that would be stapled to the crew’s Production Day Sheet. (See my January/February 2018 Cleanfax article for more on this.) In my company, the ERS informed both our office and my maintenance technician that an item needed repair. Plus, after the field technician’s initial analysis, the office could decide on sending the equipment out for repair or doing it in house, and repair parts could be ordered immediately.

We set up a “repair depot” area in our warehouse where (if possible) all red-tagged equipment went. We also stocked commonly used repair parts here along with a workbench and tools. This area was the realm of our repair/ maintenance technician.

Note: I highly recommend you create a (usually part-time) maintenance technician position. After all, my field techs despised coming in after a long day and having to clean and restock their service vehicles. In addition, I discovered this extra, hated hour or so per day inevitably pushed my techs into overtime by Thursday or Friday. So, in effect I was paying my techs time and a half for work they hated.

Once I realized this, I hired a reliable, mechanically inclined high-school kid (Yes, they are out there!) to come in for three hours, five nights per week. He would first check any pending ERS forms to set his priorities for the shift. He would also restock and clean all company vehicles, plus clean up our shop and offices. This new position worked great.

The one common denominator that all three sections of my Equipment Repair Sheet (to be filled out by field tech, repair tech, and office personnel) shared was “How can we keep this damage from happening again?” If needed, we would bring up this ERS topic in our company staff meeting and seek more input and/ or share the new changes in our procedures.

The result

The Equipment Repair Sheet (along with each crew’s daily Production Day Sheet) was a “core document” in growing my company into a critical mass business. The ERS let my office know not to send this item out; plus, it added a “sense of urgency” to get it fixed fast. And thanks to this ERS, we always had a road map that added accountability as in: What is the next step? Who will do it?

Most importantly, I had a procedure focused on how to keep a breakage from happening again. Why is this important? Because building a critical mass business is an ongoing process of incremental improvements to your business infrastructure.

Implementing this Equipment Repair Sheet will be an essential step in your quest for business perfection. Are you ready? Then let’s do it.

Steve Toburen started and ran a world-class cleaning and restoration firm for over 20 years. He is now the director of training for Jon-Don’s Strategies for Success program. Steve also founded HomeFrontSuccess.com, a resource portal with training programs for contractors working in customer’s homes. Reach Steve at [email protected].