The Daily Maintenance and Restocking Checklist

By Steve Toburen

Transforming a cleaning and/or restoration operation into a critical mass business that can run without you is like building a “house of cards.” Yank one card out, and everything collapses! And, yes, when your techs run out of one essential item or their equipment fails, your business — and your profits — “collapse”!

To grow into a critical mass business, your mission as the owner (or manager) is to A) anticipate problems before they happen; B) develop systems to proactively prevent these issues; and C) make sure your new procedures are followed. (You must also monitor the results and adjust your procedures as needed.)

Over the years (with a lot of false starts and pain!), I developed a smoothly running business infrastructure of written systems and procedures. I then built a great team led by managers who demanded employee accountability. With my solutions (procedures), straight out of my “Strategies for Success” training program, you can do the same.

Your challenges

It is the constant feast-or-famine cycle of our industry. Your company is dead in the water with zero calls! (“Sally, will you check the phone again to make sure it has a dial tone…”) In this scenario you have too much time for maintenance and restocking.

But more likely, business is crazy with your phone ringing off the hook (You water mitigation contractors know what I mean!), and your employees have zero time for maintenance and restocking. You’re screaming at your exhausted techs, “Get out there and clean and restock your vans!”

Plus, your workers don’t want to deal with fixing broken stuff, so they simply… don’t. And off goes the equipment to not work again out in the field. (See my Equipment Repair Sheet solution in the September issue of Cleanfax.) Your equipment and vehicles run — until they don’t (and always 30 miles from the shop during rush hour!).

Or your tech desperately calls from a job to say, “I’m out of detergent, prespray, pet treatment, and rust remover all at the same time.” (Tech nervously laughs.) “What are the odds?”

After screaming (and maybe pounding your phone on the desk), you rush out into your shop and discover virtually your entire chemical inventory is out of stock! And you don’t have any spare parts for your equipment, either.

The above scenario repeated itself far too often in my company. It was destroying my profits, demoralizing my staff, and ticking off my customers. Even worse, I wasn’t having fun anymore. Something had to change!

Steve’s solution

In business, the old saying is true: “When Nobody is assigned to a task, that is who always does it… Nobody!” So, who could I assign the daily tasks of cleaning my trucks and equipment, restocking and checking reorder levels, and doing minor repairs?

Not my overworked techs. They hated that stuff. Even worse, the extra time required for cleaning and restocking inevitably pushed my employees past 40 hours per week. Basically, I was paying my techs overtime to grudgingly do this work.

Then inspiration struck! I created a new part time position, maintenance tech (MT). I then hired a reliable young person (They are out there.) who was handy with basic tools and repairs. Note: I paid my maintenance tech more than he or she could earn working at McDonalds, so the job was really appreciated. But what my MT earned was far less than my techs were making, so I still came out way ahead.

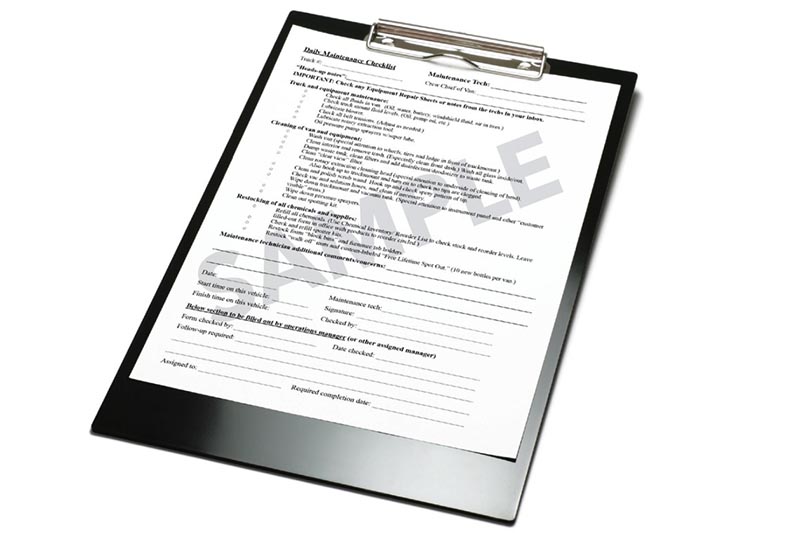

Since, many times, my MT worked after hours, unsupervised, both communication and accountability were essential. So, I needed to add another form to my business infrastructure: A Daily Maintenance Checklist that was filled out for each vehicle. Here’s how the system worked in my company:

Our maintenance tech would clock in Monday through Friday at 4:30 p.m. and have a brief meeting with our operations manager. If any crews had already checked in, their completed Production Day Sheet (see the January/February 2018 issue of Cleanfax) would be checked for any equipment problems or other issues to address.

The MT would quickly go over the Daily Maintenance Checklists their supervisor had already prepared and review any pending Equipment Repair Sheets. Since our trucks didn’t usually drag in until 5:30 or 6:00, my part-time MT still had a window of open time. He or she used this time to clean and organize the warehouse and then, after most of our staff left at 5:00, the office. There was trash to be dumped, bathrooms to be cleaned, floors to be swept and mopped, and carpet to be vacuumed. Remember, if Nobody is assigned the task…

As each crew arrived, the MT would greet them with high-fives all around. (Remember, a team of great people bonds together based on emotions — not paperwork!) Then the crew chief would share any issues for our MT to note on the truck’s Daily Maintenance Check List.

Our maintenance tech would check off each step in the three sections of the Daily Maintenance Checklist. First, he or she would do routine maintenance on the vehicle, truckmount, and equipment — the stuff Nobody focuses on until it breaks down.

The MT would then clean vehicles inside and out including all normally carried equipment, and, lastly, restock all the chemicals and supplies while noting any that needed to be reordered. These different tasks were checked off as performed and notes were written to the office as needed. With four truckmounts, minor repairs, and light cleaning in our 6,000 square-foot office and warehouse, my MT normally worked a four-to-six hour shift every night.

The result

Remember, a critical mass business requires both communication and accountability. My Daily Maintenance Checklist encouraged written, two-way communication while also promoting a logical work routine with checked-off steps. All of us do better with a structured, consistent routine. (A critical mass business thrives on consistency!)

Accountability? The bottom of the checklist, which was “to be filled out by operations manager,” was always staring my MT in the face. He or she knew there would be follow-up questions. Your employees desperately need to be held accountable with either (hopefully) positive public recognition or private reminders with specific action steps for improvement (and the consequences if they do not improve).

Implementing the Daily Maintenance Checklist, assigned to a reliable, part-time maintenance technician, transformed my business. My production technicians could focus on what they did best — cranking out quality work while making customer cheerleaders for my company. Then these tired workers could hand the reins over to my maintenance tech and head home (or to the closest happy hour).

My company morale increased dramatically when employees walked in each morning to a clean office and shop with shining, restocked vehicles. And my production (and profits) increased because regularly maintained equipment was much more reliable with far fewer breakdowns.

My company morale increased dramatically when employees walked in each morning to a clean office and shop with shining, restocked vehicles. And my production (and profits) increased because regularly maintained equipment was much more reliable with far fewer breakdowns.

The Daily Maintenance Checklist was an essential building block in my business infrastructure that introduced sanity to our daily business operations. My team of the “very best people” were focused on a common goal and vision: Creating a smoothly running critical mass business. And, yes, my Daily Maintenance Checklist was the super glue that kept our house of cards (which really is any small service business) from falling down.

Steve Toburen started and ran a world-class cleaning and restoration firm for over 20 years. He is now the director of training for Jon-Don’s Strategies for Success program, which includes a complete, turnkey business infrastructure for cleaning and restoration companies. Toburen also founded HomeFrontSuccess.com, a resource portal with training programs for contractors working in customer’s homes. Reach Steve at [email protected].