Effectively Using Carpet Rinses

By Tom Forsythe

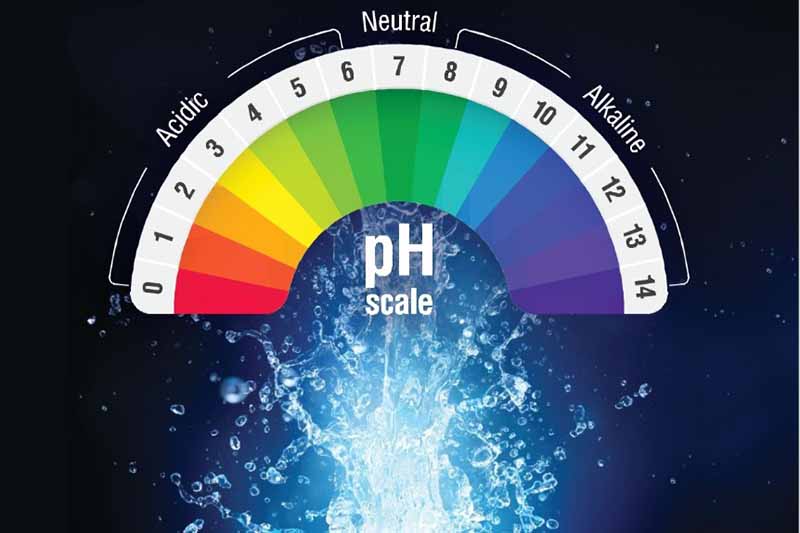

As with all chemical use in professional cleaning, the key to successfully using rinses is understanding the chemicals themselves. Both acidic and alkaline rinses offer exceptional aid in removing soils from carpet, but each provides usefulness under specific conditions. Each also offers special considerations that can change the outcome of cleaning. Let’s review the main points of each rinse type and how our cleaning can benefit most from them.

Acidic rinses

Some acidic rinse formulas are designed as neutralizers, while formulas that have other acidic builders and high amounts of surfactants qualify as emulsifying rinses. All acidic rinses contain appropriate corrosion inhibitors that protect the metal parts in your equipment.

An acidic neutralizing rinse is primarily acidic, and sometimes an anionic hydrotrope or surfactant may be added to help break surface tension. This type of rinse will lower the alkalinity level of carpet after the emulsification of the prespray. The emulsification of oils and soils uses up some alkalinity in the prespray. The remaining pH of the carpet fiber is more a result of the total alkalinity of the prespray and the amount of oily soil emulsified than of the neutralizing rinse.

It is important to remember that low levels of acidic builders in neutralizing rinses reduce the thoroughness of the rinse. A neutralizing rinse depends more upon the lift of the vacuum in removing soils than on an acidic builder designed to help carry away soils in the water stream.

An acidic emulsifying rinse contains acidic builders and is designed to work with all carpet presprays. When you use an acidic emulsifying rinse for extraction, you accomplish several things at once and receive a cleaning and rinsing boost.

Acidic builders are designed to attach to the soil emulsified by any prespray and rinse it thoroughly out of the carpet at high dilutions. If the prespray has not completed the emulsification process, the rinse will finish this process in the rinsing step.

In addition, any alkaline residues in the carpet fibers will be neutralized by the rinse, which typically includes a low-foaming surfactant with good wetting characteristics that will help hold the diverse ingredients in a stable solution. The right surfactant forms a brittle residue which, along with an added polymer, helps leave the carpet in a state in which re-soiling issues do not occur.

Superior results with acidic rinses

Powdered acidic emulsifying rinses developed within the last decade have proven to be better cleaners than their processors thanks to their different levels of key ingredients. Acidic neutralizing rinses also are now less expensive, and the ingredients are not used up by hard water. Acidic emulsifying rinses have ingredients that soften water in rinsing.

If you do not use a water softening system, the logical choice is to use an acidic neutralizing rinse. Both emulsifying rinses and neutralizing rinses can be used for cleaning upholstery with natural fibers and wool carpet and will soften fibers and limit browning. Acidic emulsifying rinses will more readily result in brighter and cleaner carpets while reducing the likelihood of other problems like wicking and re-soiling.

Also note that you do not need to turn off acidic emulsifying rinses at the truck when prespraying. Tests indicate that the pH of even moderate alkaline presprays is not significantly affected and that the diverse cleaning additives in acidic emulsifying rinses balance any impact on the pH of the prespray.

Alkaline rinses

For effective cleaning with an alkaline rinse, you must first understand the type of rinse you are using. Alkaline rinse formulas are divided by pH level: neutral (pH 7-8), moderate (pH 9-10), and high (pH 11+).

The key ingredient in alkaline rinses is phosphate. Sodium tripolyphosphate (STPP) is the primary phosphate used in powders, and tetrapotassium pyrophosphate (TKPP) is the primary phosphate used in liquids. Both of these phosphates have a moderate pH of 9 to 10. Products in this pH range will have the highest amount of phosphate, which is the most effective ingredient available to prevent redeposition of soils and has the ability to carry the most soils away in the water rinse stream.

A neutral-pH rinse can be used safely on natural fibers. A high-pH rinse adds a second level of cleaning for fibers in need of restorative cleaning. The moderate-pH rinse is the primary alkaline rinse used by professional cleaners.

Alkaline rinses contain more than just phosphates. In high pH rinses, you will also find sodium metasilicate and sodium carbonate making up a high percentage of the alkalinity; in neutral rinses, sodium bicarbonate and acidic phosphate make up a high percentage of the alkalinity.

Corrosion inhibitors may be added beyond sodium metasilicate, which serves as the inhibitor of choice for alkaline rinses. Surfactants usually will be used to help the rinse penetrate deeper and faster into the carpet before the almost immediate extraction.

Some ingredients, such as solvents and hydrogen peroxide, are not used because the level of dilution makes them ineffective in rinses. Polymers are sometimes used to neutralize the propensity of some ingredients to attract soil; however, the high dilution prevents any possibility that the rinse will provide any stain resistance after its use.

Superior results with alkaline rinses

Once you select the rinse pH, you must determine the quality of water you will use. If treated water (reverse osmosis, deionized, or softened) is not used, the phosphate in the rinse will immediately soften hard water in the solution hoses before being sprayed out of the wand jets, effectively wasting much of the phosphate needed for cleaning.

In lab testing, we determined that, at a 1-to-640 dilution in hard water of 15 grains, 80% of the phosphate is used up softening the water. This means only 20% of the phosphate was available to perform its designed cleaning functions. Therefore, it is highly recommended that water be treated before using an alkaline rinse.

Finally, note that high heat is especially useful in breaking down any remaining oils not already broken down by the prespray. The high-pH rinses designed for restorative cleaning and oil-bonded polyester fibers benefit the most from high heat. It is important to remember that high heat with hard water causes the minerals to leave the water stream and bond more readily to metal parts of the truckmount system like jets and quick connects.

In short, rinses are an excellent way to make sure you are leaving carpet as clean and residue-free as possible, but understanding the types of rinses is key to that success. Alkaline rinses are most beneficial when additional cleaning may be necessary. For fibers that do not need to be neutralized, you may primarily use an alkaline rinse. When neutralization or emulsification of oils is needed, cleaners can turn to acidic rinses.

Tom Forsythe, chemical product director for Aramsco, has developed more than 200 chemical products in the last 23 years.