Changes and Challenges of the Global Flooring Market

By Claudia Lezell

As floorcovering and related materials evolve, the design, build, maintenance, and related industries face a major conundrum. Slip, trip, fall, and hard surface floorcovering claims have now soared into billions of dollars. Is a floor-failure epidemic inevitable?

After years in various roles in the floorcovering industry, including as an inspector, consultant, and trainer, I’ve seen various changes, conditions, and challenges in the industry and have developed hopeful solutions.

Root-cause analysis

Problems arise when standards, or lack of standards, conflict with specification and product performance. A paradox can occur when over-expectation and misspecification outweigh material performance capacity and the fight to save the planet’s resources.

Inspection and consulting work are needed due to over-expectation of product, lower-quality workmanship, and misconception of product performance characteristics. With recent advancements in technology, we have entered an exciting, yet challenging and sometimes frustrating, time. Because of new technologies and sustainability, materials are becoming stronger, more chemically resistant, biodegradable, and recyclable. But these positive changes come with unintended consequences and conditions that are created from complacency with the status quo, naiveté, and unfortunately, subject-matter ignorance.

What I have learned most during the past 35 years in this industry is that, with the rapid advancements in technology and global influence, the materials of 35 years ago are no longer produced. Floorcovering and associated materials continue to evolve.

Despite ongoing efforts to educate, certify, and revise or develop standards, as these advances are made, the cost of claims rises. This became even more apparent when one of my colleagues saw his claim value climb into the tens of millions. Big numbers. Big challenges.

Over the last generation, there was a surge in construction demand. While this had a positive effect on our economy, it had a downside that included substandard products sometimes being used; material shortages; sloppy or too broad specifications; “devalued” engineering to accommodate cheap, fast-track construction; sloppy workmanship — such as concrete being placed and covered too quickly with floorcovering; and ineffective job staging.

Add to this the complicating factors that more severe weather conditions bring, and you have a prescription for product failure and moisture intrusion that can result in mold and indoor air quality problems.

For floors, the bottom line is this: A one-size-fits-all construction specification for below-grade, on-grade, and above-grade floorcovering installation does not work.

Floor system failure: Who done it?

By the time a floor failure hits my desk, I often have to spend more time undoing the damage from those more interested in proving it wasn’t their fault than working with a forensic team to solve the problem. Being the last one in requires time, testing, and expense in order to “get to the bottom of it.”

A repeating pattern in this type of analysis is often referred to as the “domino effect.” During our investigation process, one answer usually leads to another question and the individual components of the failure weigh one on another like a set of falling dominos.

Foundation and soil

Usually I start literally from the ground up. The term “soil” can be defined many ways. A geologist defines “soil” as an altered rock. A soil engineer will say it’s the material that supports or loads a structure at its base. Others might define it as a combination of boulders, gravel, sand, silt, clay, and organic matter. Soil provides support for the structure, shapes, and forms the final grade, and in some instances, provides disposal for household sewage.

According to the PCA Soil Primer, a booklet published by the Portland Cement Association, “The moisture or water content of a soil is normally a percentage of the oven dry-weight of the soil, as tested by ASM D2216 or AASHTO T265.” Soil moisture is of three different types: Gravitational water, capillary water, and hygroscopic water.

Soil type, size, compaction, moisture content, chemistry, drainage, or even testing can play a role as one of the “culprits” in floor failure. For instance, if a soil is not compacted well or varies in soil chemistries throughout the site, concrete floor flatness (FF) or floor levelness (FL) will be affected, causing undulations, which can affect some or all of the components of the entire floor system.

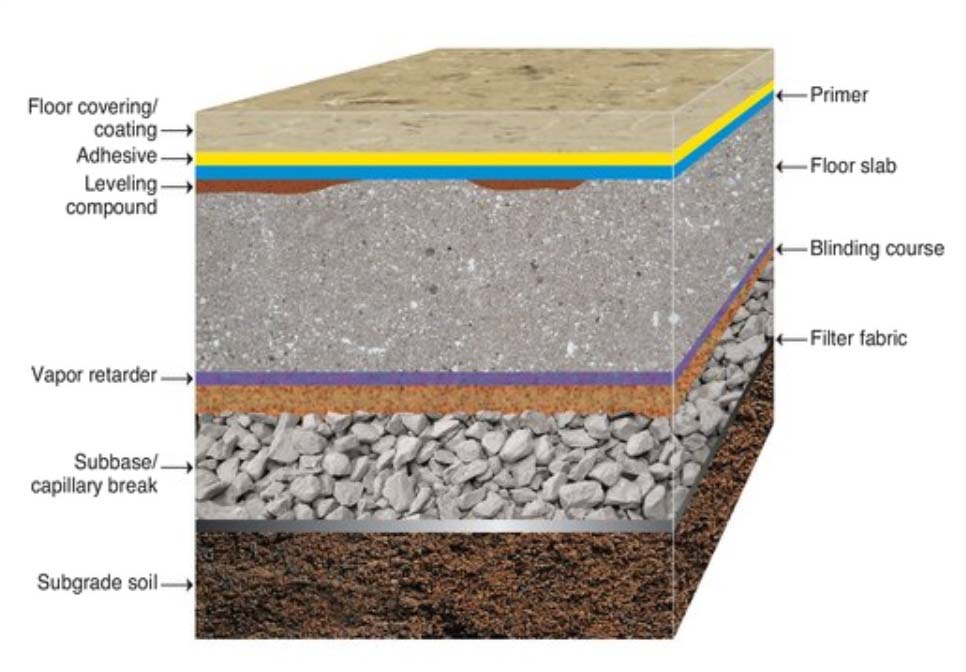

Image 1: Schematic representation of the components in a slab on ground floor system. Image courtesy of Portland Cement Association and National Ready Mix Concrete Association.

Soil and transmission of moisture in soil can seriously affect concrete and flooring by eliminating or degenerating the vapor retarder and using a vapor retarder with a lower permanence rate. According to Howard M. Kanare, in the book Concrete Floors and Moisture, “Vapor retarders must have a permanence rating less than 0.3 perms, according to ASTM E1745. There is no standard specification for vapor barrier compared to vapor retarder. However, ACI 302.1R states, ‘True vapor barriers and products have a permanence (water-vapor transmission) rating of 0.00 perms when tested in accordance with ASTM E96’.” It is generally accepted in the construction industry that a material having a permanence rating less than 0.01 perms is considered a vapor barrier.

In our investigations relating to concrete slab on ground (grade), even if a vapor retarder is present, it sometimes doesn’t meet the criteria of what is stated previously in the ASTM E1745 regarding vapor retarders. In many instances, mil thickness is mistaken for permanence.

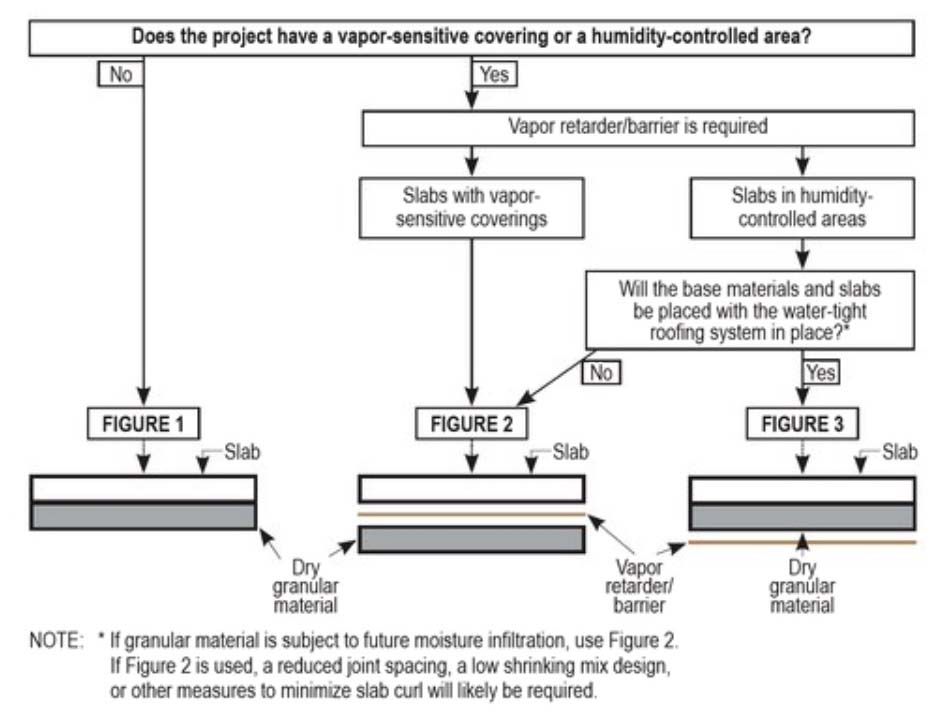

I also have been on investigations in which, if a vapor retarder is used with no barrier because of expense, it sometimes does not conform to the adaptation of installation requirements made to ACI 302.1R. Image 2 is a flow chart adapted from ACI 302.1R-04 in Concrete Floors and Moisture. The chart description says, “It permits omitting vapor retarder for floors without floor coverings where humidity will not be controlled, such as unconditioned warehouse space.” However, it further states that “adaptive reuse and installation of flooring in such spaces often leads to flooring problems due to subslab moisture. Therefore, vapor retarders should be considered for use under all floor slabs.”

I have seen many floor failures in which the assumption was a vapor retarder was directly underneath the slab, only to face thousands of dollars in floor-failure expenses because one was nonexistent, degenerated, improperly specified, only located in a portion of the retrofitted warehouse, or specified to go under the dry granular material.

Surprisingly, some specifiers continue to support the use of vapor retarders under the dry granular fill instead of directly under the slab. This was changed in ACI 302.1R in 2004 after the concrete industry recognized that, if the vapor retarder is placed under this dry granular fill but gets wet in construction, it can unintentionally provide a moisture reservoir through a “bathtub affect.”

Now let’s examine the other components of the system that can be affected by vapor transmission from the soil or emission from the concrete slab.

Concrete-floor slab

Recently a flooring contractor called with a “floor emergency.”

The moisture suppression membrane manufacturer would not allow him to install thousands of square feet of floorcovering in a high-profile commercial building until he proved the moisture levels, concrete surface pH, and porosity criteria complied with their installation guidelines and industry standards.

Allegedly incorporated into the concrete mix design and specification was a “hard” steel trowel, concrete finish, and a dissipating curing compound. However, this type of finish and the use of this curing compound was in direct conflict with the specifications of the adhesive and moisture suppression membrane manufacturers’ specifications.

In this instance, the adhesive and moisture suppression membrane manufacturer were the same. The technical data sheet specifications on the sealer stated, “Substrate preparation, moisture, and alkalinity testing must comply with ASTM International, Designation: F710-11 Standard Practice for Preparing Concrete Floors to Receive Resilient Flooring.”

However, under Section 4.2, General Guidelines of the F710-11, it says, “The surface of concrete floors to receive resilient flooring shall be free of dust; solvent; paint; wax; oil; grease; residual adhesive; adhesive removers; film-forming curing compounds; silicate-penetrating curing compounds; sealing, hardening, or parting compounds; alkaline salts; excessive carbonation or laitance; mold, mildew, and other foreign materials that might affect the rate of moisture dissipation from the concrete, the adhesion of resilient flooring to the concrete or cause a discoloration of the flooring from below.” This is in direct conflict with the use of dissipating curing compounds in the concrete mix design and specification.

Image 2: This flowchart was adapted from ACI 302.1R-04. Image courtesy of the American Concrete Institute.

To make matters worse, the curing compound manufacturer claims their product will break down and deteriorate upon exposure to traffic and UV light. The manufacturer further states, “Dissipation begins approximately four to six weeks after application.” In addition, it states that a simple cleaning will completely remove the curing compound and is all that is needed to receive application of coverings, coatings, or sealers. Yet, in this particular instance, because of time and assurance of complete curing compound removal, the curing compound manufacturer’s proposed solution was to use a concrete floor stripper. This removal method is also in direct conflict with ASTM F710-11 as it requires non-chemical methods, such as abrasive cleaning or bead blasting, including methods described in Practice D4259, to remove harmful residues.

Worse still, with chemical abatement for asbestos and the various adhesive removers introduced over the years, if certain chemicals, especially strippers, are not completely removed from the concrete, any sealers, underlayments, or adhesives are in jeopardy of breaking down.

The problem here was that the installation contractor was being asked to prove the slab complied with the adhesive and sealer installation guidelines, which include pH, porosity, and moisture testing, before the manufacturer warrantied their products. This can be difficult to prove through petrographic and chemical lab analysis. Had the involved parties been better educated on the products specified and their compatibility limitations, this very reactive situation could have been avoided or reduced.

As evolving resources and materials have demanded more of the building industry, we have seen advancements in several areas. For example, concrete technology has grown over the years to include an increased selection of admixtures such as high-range water reducers commonly called super plasticizers, pozzolans, accelerators, and retarders. These chemicals can alter the time it takes for the concrete to set (shortening or lengthening the time, depending on the need). In addition, concrete can be made stronger and with less water required to hydrate the mixture. Rapid-drying concrete has hit the market, claiming it cuts the construction schedule by 30 percent.

At a recent concrete industry Strategic Development Council (SDC) Forum with various discussions of concrete-related floorcovering failures and LEED, green, and sustainability initiatives, the alternative cementious materials Initiative stood out as particularly important. The initiative’s mission is to identify green cement as an Industry Critical Technology. The Accelerated Technology Implementation website is designed to house and coordinate all efforts of SDC in support of the green cement technology in the concrete industry.

In the same vein, proper concrete mix design and performance is of the utmost importance, yet there remains some confusion about testing standards. For instance, the way concrete is tested for moisture has come under scrutiny — including three ASTM standards for testing the relative humidity in and on concrete versus the use of calcium chloride to obtain the moisture vapor emission rate. Many articles have been written on this subject. A good place to learn more about concrete moisture testing certification is through the International Concrete Repair Institute.

Underlayments, adhesives, and floorcoverings

While concrete technology has been moving forward by leaps and bounds, so has the technology of floorcoverings. For example, with resilient products, less permeability has led to improved cut and surface quality, and edge-tile formats enjoy a broader selection of sizes and shapes. We also have seen the advent of more heterogeneous types of products, which combine core materials used in other products, and even the combination of dissimilar hard surface and textile products. For example, the textile industry incorporates resilient flooring by attaching PVC backings to carpet tile.

Versatility and diversity are also prevalent in the types of raw materials that are frequently used in the construction industry. Designers and technicians alike have access to a plethora of choices today including unique and exotic species of wood from around the world and a variety of flooring mediums (including a multitude of textures from specialty ceramics and glass to stone and stained concrete). In addition, the science of wood identification is advancing through molecular, chemical, and DNA methods.

However, in the discussion of all these new advancements, we would be remiss if we did not acknowledge that some of the advancements are accompanied by new challenges. One often encounters restrictions or necessary accommodations when incorporating the new materials. Although aesthetically pleasing, one must not forget that exotic raw materials can bring with them idiosyncratic sensitivities to species and origin identification, moisture, alkali, or dimensional growth

factors. If untrained labor sets these materials in an unclimatized environment with moisture and alkaline-related conditions, a significant and costly failure can occur.

In addition, certain environmental restrictions, such as the elimination of asbestos and chlorinated solvents, have caused adjustments in the way products are manufactured, installed, maintained, and disposed of. The subject of lead and silica, regarding floorcovering, is also under government scrutiny and regulation, thus adding to the long list of necessary adjustments to be made in manufacturing, recycling, waste management, specification, handling, installation, and maintenance.

One example of environmental restrictions is the stringent rules and regulations on emissions and the release of kiln gases into the atmosphere. This has led to changes in the composition of cement, affecting the properties of concrete and control of alkali.

Maintenance

Technological advancements in maintenance products and procedures have resulted in more durable floor finishes and sealer formulations being developed. Evolving technologies and techniques, such as dry buff, Nano, and UV-cured site-applied finishes, have also made it to the forefront. The green-cleaning movement has introduced alternative approaches to cleaning such as enzyme cleaning.

For both practical and commercial reasons, biotechnology is already widely used in North America and Europe. Numerous contract cleaners and building managers now use enzymes and bacterial solutions for general cleaning, sanitizing, and even viral control. Enzyme-based cleaning solutions are used in a large range of industrial and commercial processes. For example, in order to remove fats, grease, starch, proteins, lubricating fuel, oils, paints, and even tire marks, biological products are used.

Enzymes are proteins, composed of hundreds of amino acids, which are produced by living organisms. They are responsible for several reactions and biological activities in plants, animals, human beings, and microorganisms. They are present in the human digestive system where they break down carbohydrates (sugars), fats, and proteins present in food.

There are hundreds of thousands of enzymes, each with its own characteristics. For example, an enzyme that is the catalyst for the breakdown of protein will not react with fats and oils. Therefore, to be an effective enzyme cleaner, a formulation must contain a variety of compatible enzymes. Enzyme cleaners speed up the natural process of biodegradation.

Because of this natural characteristic, enzyme floor cleaning products fit nicely into the “cleaning green” category and are used to clean all types of floorcovering materials including epoxy grout.

Claudia Lezell owned and operated a retail flooring company for 12 years and has owned Inspections Too Inc., a flooring inspection, consulting, and expert witness service for more than 23 years. She has spearheaded IICRC hard surface certification Floor Covering Inspector Program since 1996, has participated in numerous floorcovering, specification, and construction technical committees, and is the past vice chair of the IICRC outreach committee and hard surface standards. Lezell is co-founder of the Flooring Technology Institute.