Bonnet Cleaning: Dead or Alive?

By Dennis Knapp

When we discuss carpet cleaning methods, typically at the top of the list is extraction, then dry or foam methods, followed by shampooing, with bonnet cleaning trailing at the end. Not surprising.

We keep hearing about the demise of bonnet carpet cleaning. However, it appears, at least in commercial carpet cleaning — either performed by contract cleaners or carpet cleaning professionals with commercial accounts — bonnet carpet cleaning is still going strong.

The basics

So that we are all on the same page, bonnet cleaning involves immersing a pad, referred to as a bonnet, in water, wringing it out, and attaching it to the base of a low-speed rotary floor machine with a pad driver. It is then worked over the carpet. The floor machine should not rotate faster than 300 rpms, lower is safer. Higher speeds can damage some carpets.

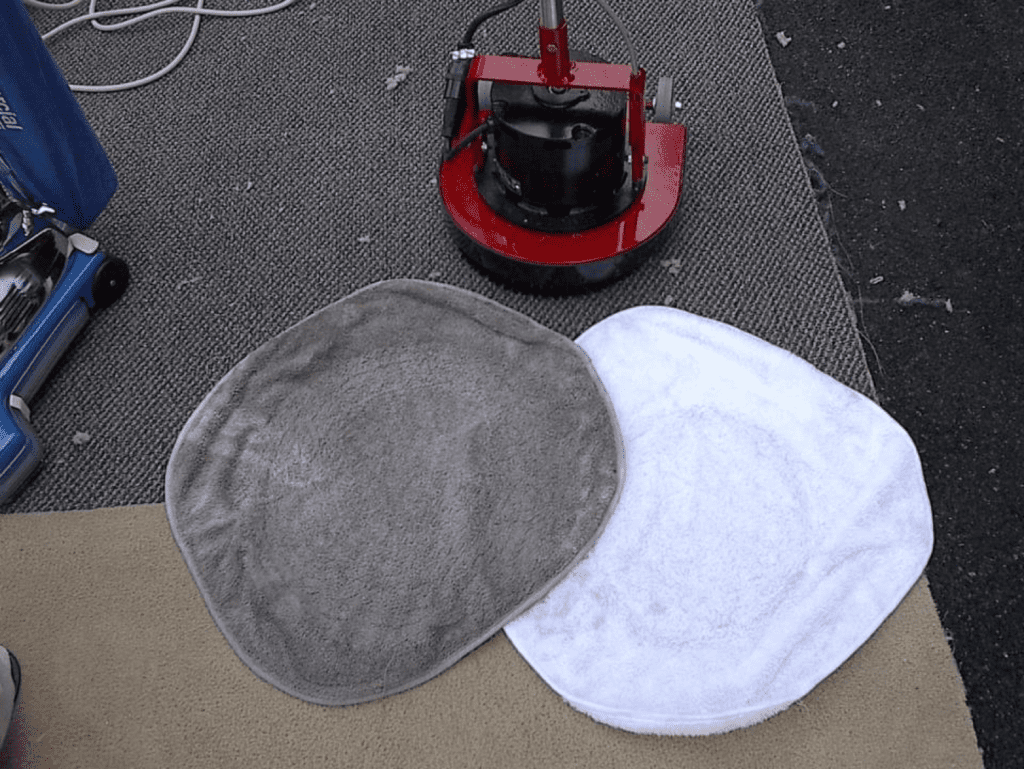

While cleaning solution can be added to the bonnet directly, today most pros soak the pad just in water and then apply chemical prespray to the carpet similar to performing carpet extraction. As the bonnet moves over the carpet, it collects soils, and as it does, pros need to make sure the bonnet does not become too soiled. The bonnet should be flipped over to a clean side about every 100 square feet and rinsed entirely after 200 feet of cleaning.

Why bonnet cleaning still matters

As to its popularity in commercial carpet cleaning, there are some very good reasons for this. Probably at the top of the list is the fact that bonnet cleaning does not require purchasing special equipment. In most cases, all that is needed is a low-speed floor machine, which most cleaning contractors and many carpet cleaning technicians already have.

However, there are other reasons bonnet cleaning remains popular as well:

- Bonnet cleaning is relatively fast and easy to perform.

- While it is not as effective as extraction, for instance, it provides a good “quick clean,” addressing and helping to remove surface-level soils.

- Bonnet cleaning is sometimes performed after carpet extraction to help pull out remaining soils in the carpet, along with chemical residue, helping to prevent rapid resoiling.

- Bonnet cleaning can help remove embedded traffic lanes so that carpet in walkways looks more even.

- It is an effective interim cleaning system; some cleaning contractors will bonnet clean carpets two or three times and then extract, which is a cost and time savings.

- While there is training involved, it typically is not as involved as with other forms of carpet cleaning methods such as extraction, dry, or foam.

- Bonnet cleaning is viewed as a low-moisture carpet cleaning process and typically results in relatively fast dry times.

However, the secret to effective bonnet carpet cleaning is very dependent on the type of bonnet used; not all bonnets are created equal. Some are cotton, a cotton-nylon blend, polyester, and microfiber. In many cases, a microfiber bonnet will prove more effective at removing soils, speed the cleaning process, and help carpet dry faster than using bonnets made of these other materials.

A microfiber refresher

A microfiber is about half the diameter of a fine silk fiber and much finer than a human hair. In fact, the fibers are hundreds of times smaller than a strand of hair. The fibers are so tiny that if you took a 16″ x 16″ microfiber towel and laid the fibers end to end, it would reach from Miami Beach to Anchorage, according to one microfiber manufacturer.

Microfibers are made of several different materials including polyester, polyamide (nylon), rayon, and other fabrics in various combinations. The characteristics of its components make microfiber particularly useful for both the commercial cleaning and professional carpet cleaning industries.

For instance, the polyester found in microfiber is an effective material for scrubbing hard and soft surfaces. The combination of fibers used to manufacture microfiber also makes it extremely absorbent, as we have discussed, which often means less chemical and water are needed. This results in several benefits for pros cleaning commercial carpets.

Some other benefits of using microfiber bonnet pads include reduced cleaning solution costs; reduced work time because more work can be completed without changing pads; promotes sustainability because less cleaning solution and water are used; and help ensuring the carpet dries faster so areas can be open to foot traffic in a shorter amount of time. Because bonnet cleaning is considered a low-moisture cleaning technique, using microfiber bonnet pads helps ensure mold and mildew do not develop in the carpet after cleaning.

Cleaning and care of microfiber bonnet pads

Another benefit of using a microfiber bonnet pad is that it is very durable and can be washed many times more and last far longer than cotton, for instance. In a study conducted by the University of California at Davis, microfiber towels could be washed 500 times, compared to just 55 times for a conventional towel, before it begins to degrade.1

However, the effectiveness of microfiber diminishes if it is not rinsed, washed, and cared for properly. The bonnets should not be washed with any other fabrics. This helps prevent lint from other materials clinging to the microfiber.

Also, microfiber pads should not be washed using bleach, fabric softener, or high temperatures. Some experts recommend using only liquid laundry detergents, rather than powders as these products may leave a soapy residue on the absorbent fibers, making them less effective. Finally, microfiber bonnets can be air dried or dried using only a low heat setting or no heat at all. High temperatures can melt microfibers.

Dennis Knapp is Director of Product Development at Impact Products LLC. Impact Products markets several microfiber products including microfiber bonnet pads used for carpet cleaning. He can be reached through his company website at www.impact-products.com.

1Based on a study entitled, “UC Davis pioneers use of microfiber mops in hospitals,” June 23, 2006.